Lean Product

What is a lean product?

Lean product definition

A lean product is a product that has been created using a lean methodology. Lean product development allows us to build products more efficiently with minimal waste while maintaining quality.

Lean product development enables businesses to save money and resources. They do this by focusing on ways to trim the fat, like removing features that add little value or allocating resources more sustainably. The end result is a streamlined development process, a reduction in time, money, and resources spent, and nothing but value left in the product.

What are the principles of lean product development?

Lean product development is a product design approach that emphasizes creating value for customers while minimizing waste and maximizing efficiency. The principles of lean product development can be summed up in five key concepts.

Value for customers: Creating products that meet the needs and wants of customers.

Value stream: Identifying and optimizing the steps involved in designing, producing, and delivering a product.

Eliminating waste: Identifying and eliminating any activities or processes that do not add value to the product to improve efficiency and reduce costs.

Customer pull: Producing products in response to customer demand to prevent overproduction and waste.

Perfection: Continuously striving to improve the product and the processes used to create it to stay competitive and meet customers' evolving needs.

How does a lean product differ from a traditional product?

The difference between lean and traditional products is how they come together. A lean product goes through a much more inclusive development process utilizing cross-functional teams. The lean product development process incorporates the following:

Collaborative team approach: All teams work together from the beginning to the end, encouraging knowledge sharing and cross-functional collaboration. This approach results in more efficient and effective problem-solving, as everyone works towards the same goal.

No communication silos: Unlike traditional product development, there are no communication silos separating departments in lean product development. This means that everyone has access to the same information and can communicate freely with each other. This results in better decision-making and faster problem-solving.

Streamlined decision-making process: Lean product development involves a streamlined decision-making process. Decisions are made quickly, and there are no unnecessary layers of bureaucracy. This makes the team more agile and responsive to changing customer needs.

Customer feedback: Every successful product has been influenced by regularly collected customer feedback in some way. This feedback is used to improve the product and ensure it meets customer needs. This approach ensures that the product constantly evolves and improves rather than being released as a finished product that may not meet customer expectations.

What are the benefits of using lean product development?

There’s a reason some of the biggest companies on the planet are using lean product development to create new products. Let’s look at a few reasons why lean product development is so popular.

Shorten development cycles: Streamlining your process helps you release products faster, giving you a head start on the competition.

Lower development costs: Reducing wasted resources means spending less on each project.

Generate innovative solutions: Trying to boil a product down to its most valuable iteration can be tough, leading to out-of-the-box thinking that pushes innovation.

Lower production costs: Lowering your development costs will translate into lower production costs.

Examples of lean products

There’s no better example of lean product development than the ones who created it: Toyota. The company changed product development forever when it realized the value of streamlining the development process. They also implemented a "pull" system, where products are only produced based on customer demand, which reduces inventory waste. Toyota's success with the lean product development methodology has made it a widely adopted approach in the manufacturing industry, with companies utilizing its principles to improve their own product development processes.

How can product managers implement lean product principles?

You need a product manager who fully understands lean product development principles to be effective. They should perform the following tasks to help businesses get the best out of lean product development methodologies.

Establish cross-functional teams that encourage knowledge-sharing and collaboration

Streamline decision-making processes to reduce waste and improve efficiency

Gather feedback from customers regularly to continuously improve the product

Prioritize the most critical features and eliminate unnecessary ones to reduce waste

Focus on creating products that meet customer needs and improve customer satisfaction.

General FAQ

Glossary categories

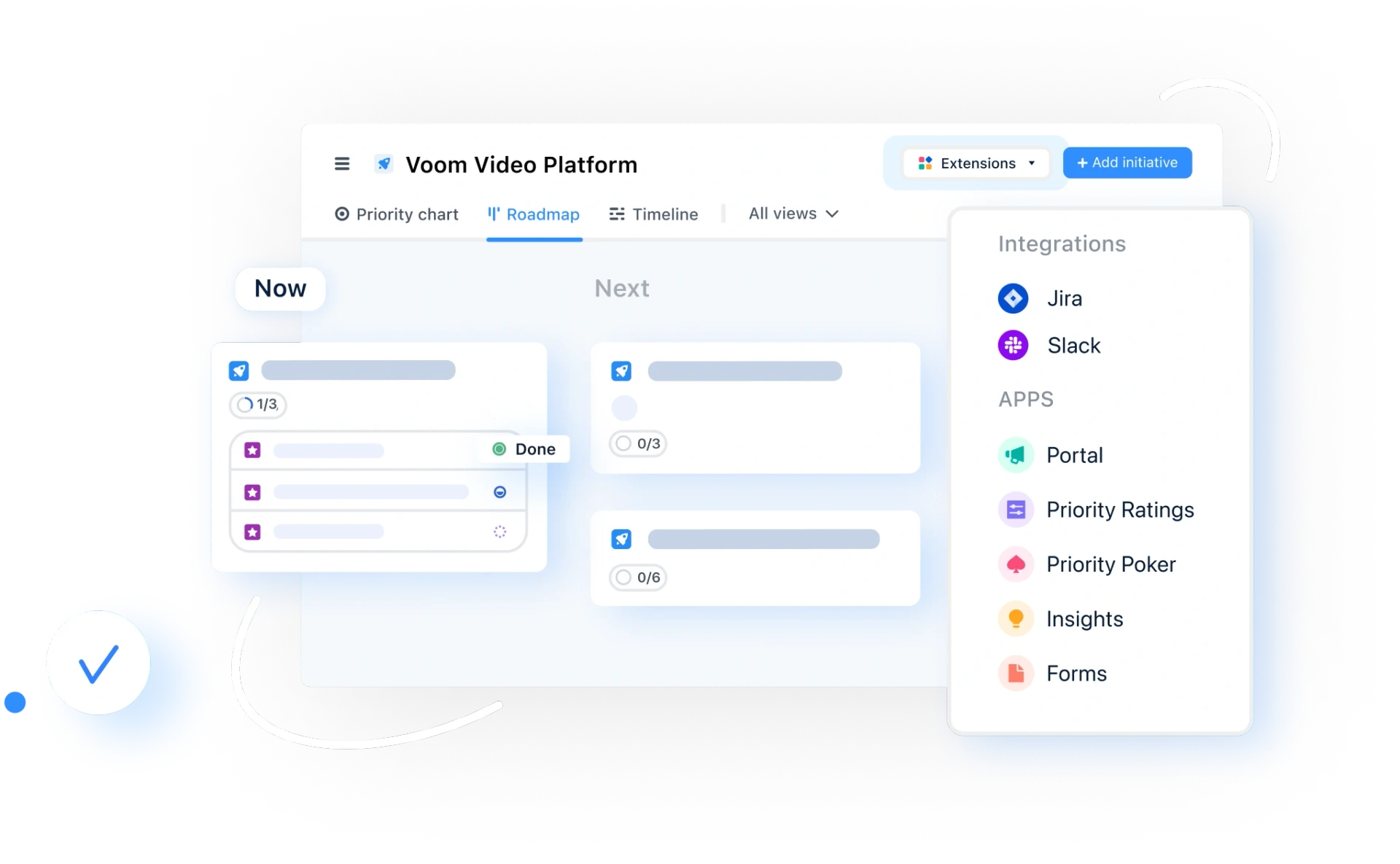

Experience the new way of doing product management

Experience the new way of doing product management