Operations Management

What is operations management?

Operations management definition

Operations management refers to overseeing business processes and ensuring maximum optimization within a business. An organization is concerned with converting resources like labor and raw materials into services and products as effectively as possible to improve its profit. Teams responsible for operations management balance revenues and expenses for optimum net profit.

Operations management is common in the manufacturing industry. Manufacturers want to create the best products as efficiently as possible for the lowest cost. That requires examining and reconfiguring their production systems, workflows, suppliers, and logistics. Operations management helps assess and redesign these systems and processes to be as efficient as possible.

What are the 4 types of operations management?

Business process redesign: This is a business management approach emphasizing the evaluation and creation of organizational business processes and workflows. By concentrating on from-the-ground-up development of their business processes, business process redesign aims to assist corporations in fundamentally restructuring their organizations.

Reconfigurable manufacturing systems: Reconfigurable manufacturing systems are built from the ground up to be adaptable, both in structure and the hardware and software. This helps it rapidly change to accommodate unforeseen changes in the market or internal system modifications.

Six Sigma - The term "Six Sigma" refers to control limits established at six standard alterations from what a normal distribution means. Jack Welch of General Electric introduced this set of techniques to all administrative, service, and manufacturing operations as part of a company-wide program in 1995.

Lean manufacturing - Lean manufacturing is a systematic approach to reducing waste in a production or service operation. Lean manufacturing also considers waste brought on by overburden and by unequal workloads.

3 essential functions of operations management

Inventory management: Inventory management ensures businesses have the appropriate stock, at the right quantities, in the right locations, at the right times, and for the right price and cost.

Delivery of goods on time: Delivering high-quality goods on time helps improve your brand reputation and increases customer satisfaction.

Quality assurance: Quality assurance ensures a product satisfies quality requirements once the manufacturing team has produced it.

General FAQ

Glossary categories

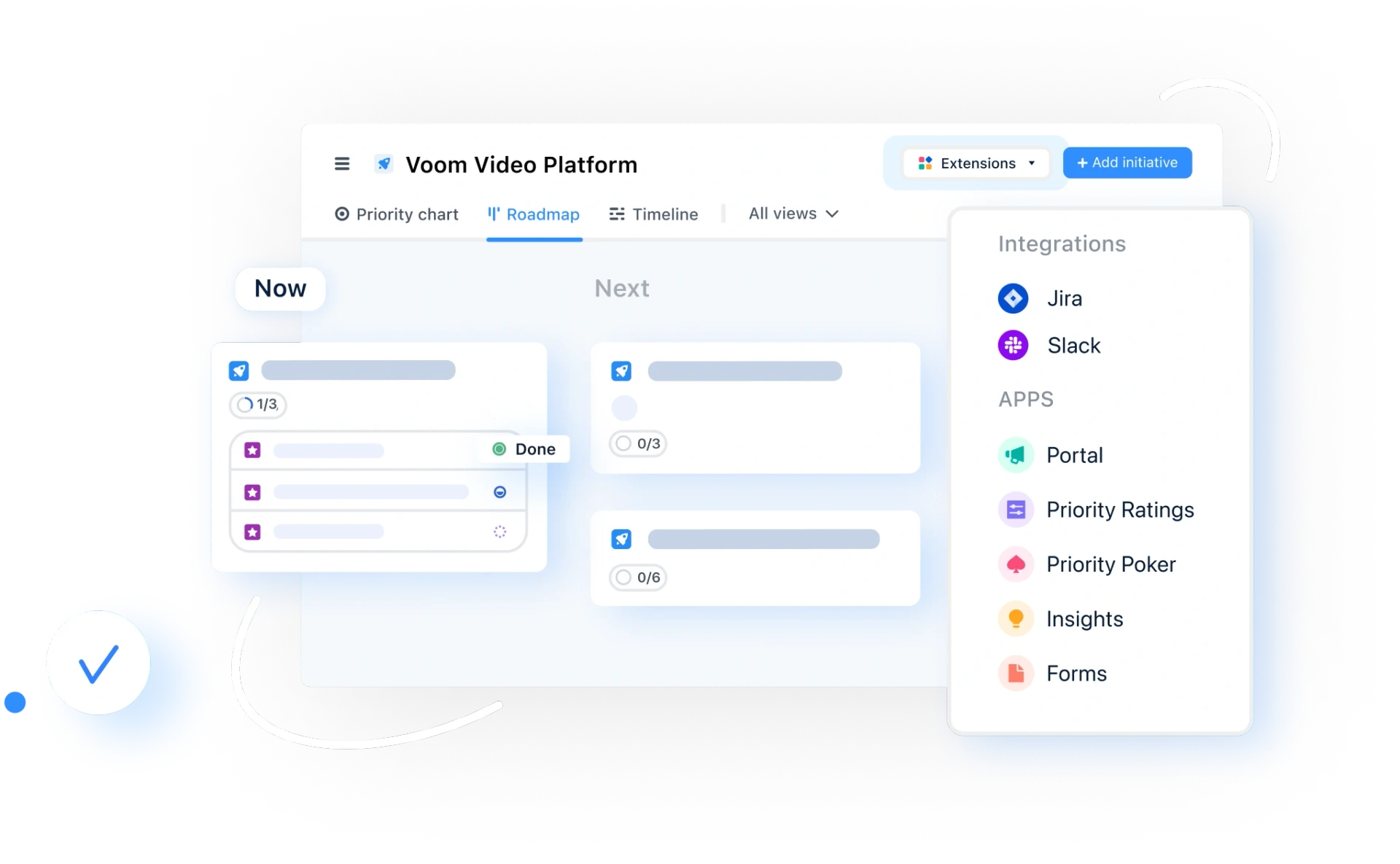

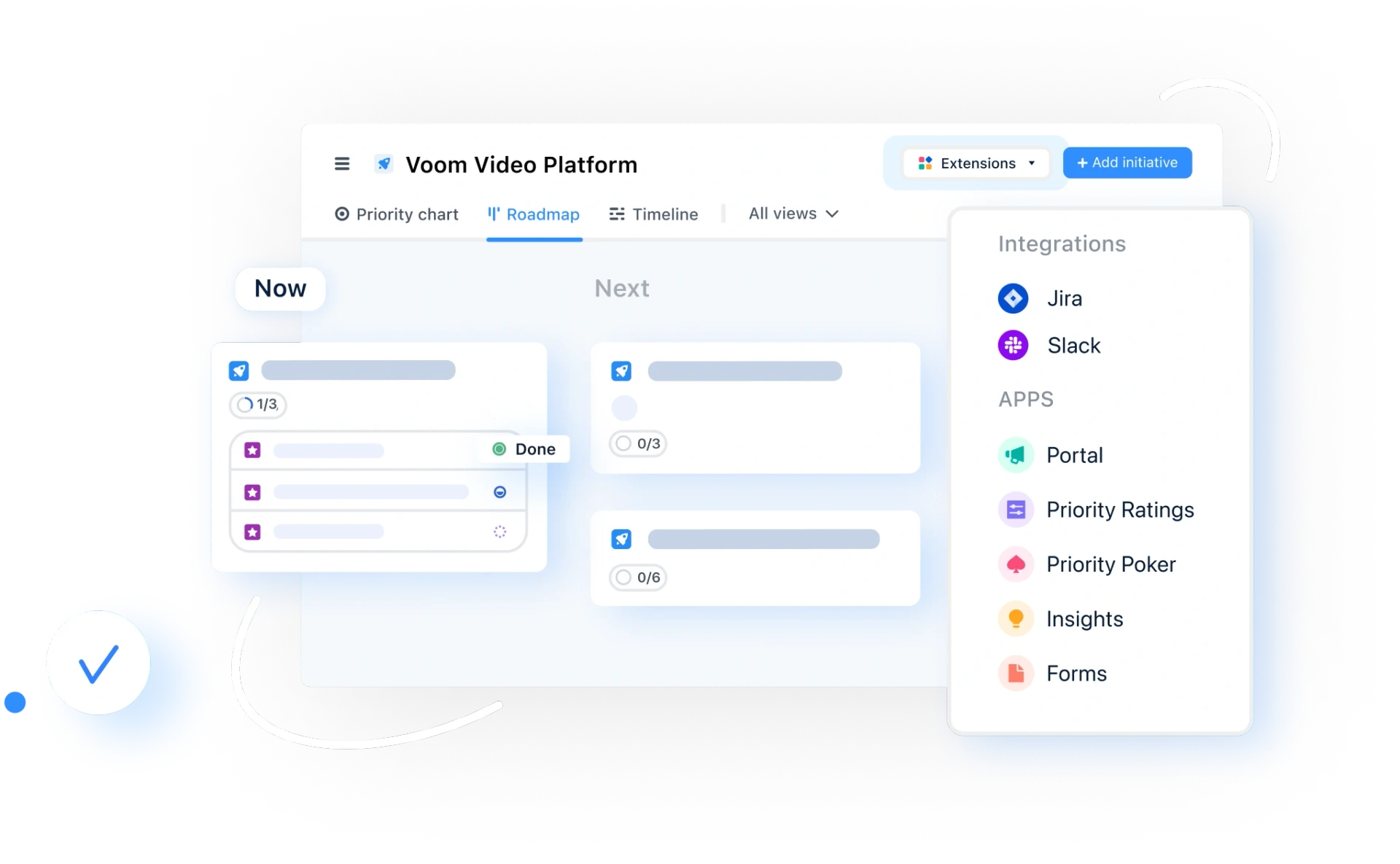

Experience the new way of doing product management

Experience the new way of doing product management