Method of Procedure (MOP)

What is a Method of Procedure (MOP)?

Definition of a Method of Procedure (MOP)

A Method of Procedure (MOP) is a comprehensive guideline for bringing a project to completion.

This shouldn’t be confused with a Standard Operating Procedure (SOP), which is a written guide informing employees on how to handle a specific task. A Method of Procedure breaks the worker’s journey to success down into explicit steps, ultimately giving them less flexibility in achieving their goals.

How can a product team use a Method of Procedure?

A product team can utilize a Method of Procedure in a variety of ways, such as building a rigid process for taking on new requests from one or more product stakeholders. They could also use a Method of Procedure for implementing new features or ideas into a product roadmap.

In the latter, a Method of Procedure might cover the steps involved and information on data supporting the necessity for adding new features or ideas.

Benefits of using a Method of Procedure

The main benefit of using a Method of Procedure is increasing employees’ efficiency and the likelihood of achieving success. Companies can leverage a Method of Procedure to eliminate guesswork and reduce the risk of human error (both of which can lead to costly mistakes).

When an employee has a step-by-step guide to follow, their focus should become tighter and they’re less likely to waste time figuring out their next action.

General FAQ

Glossary categories

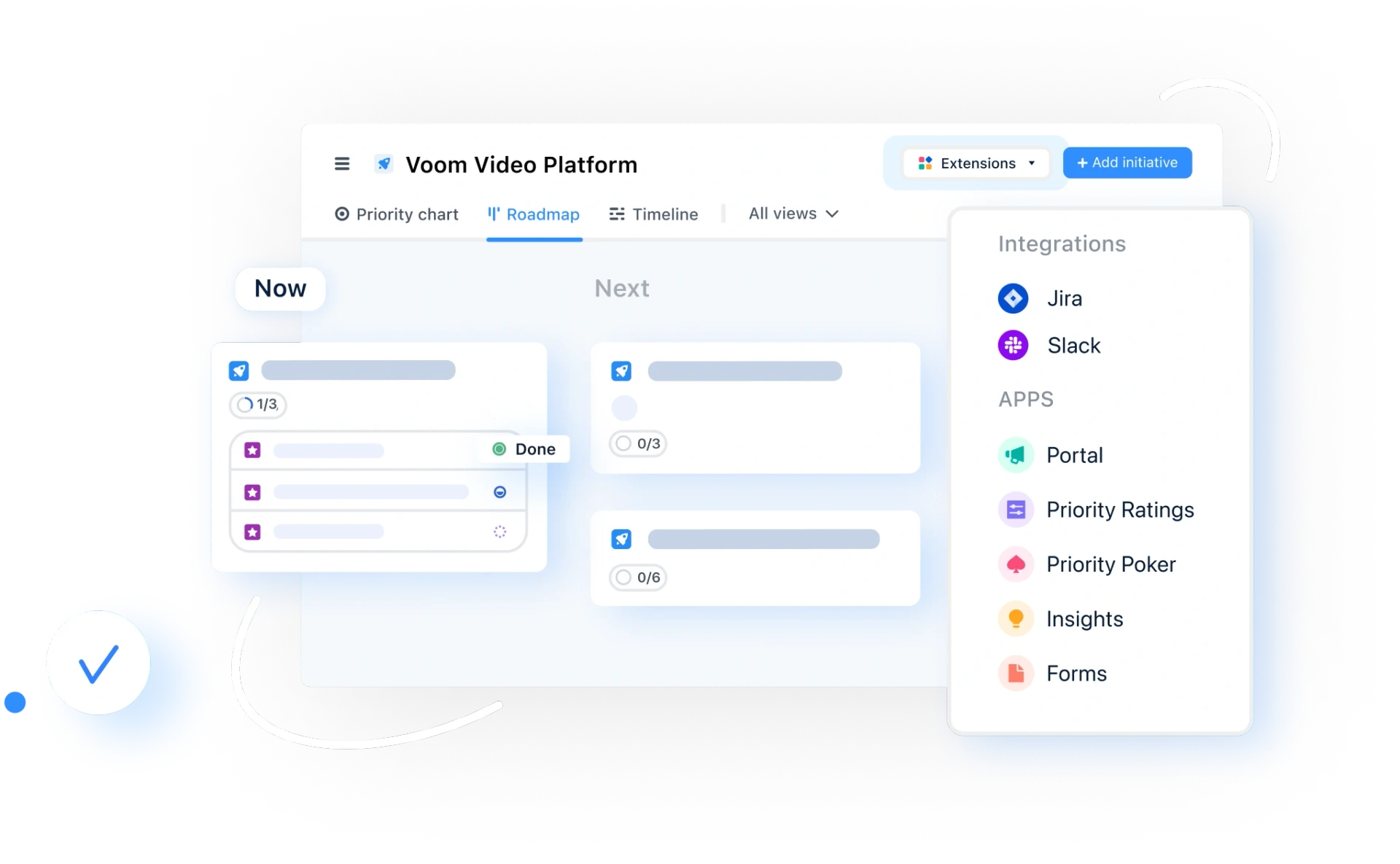

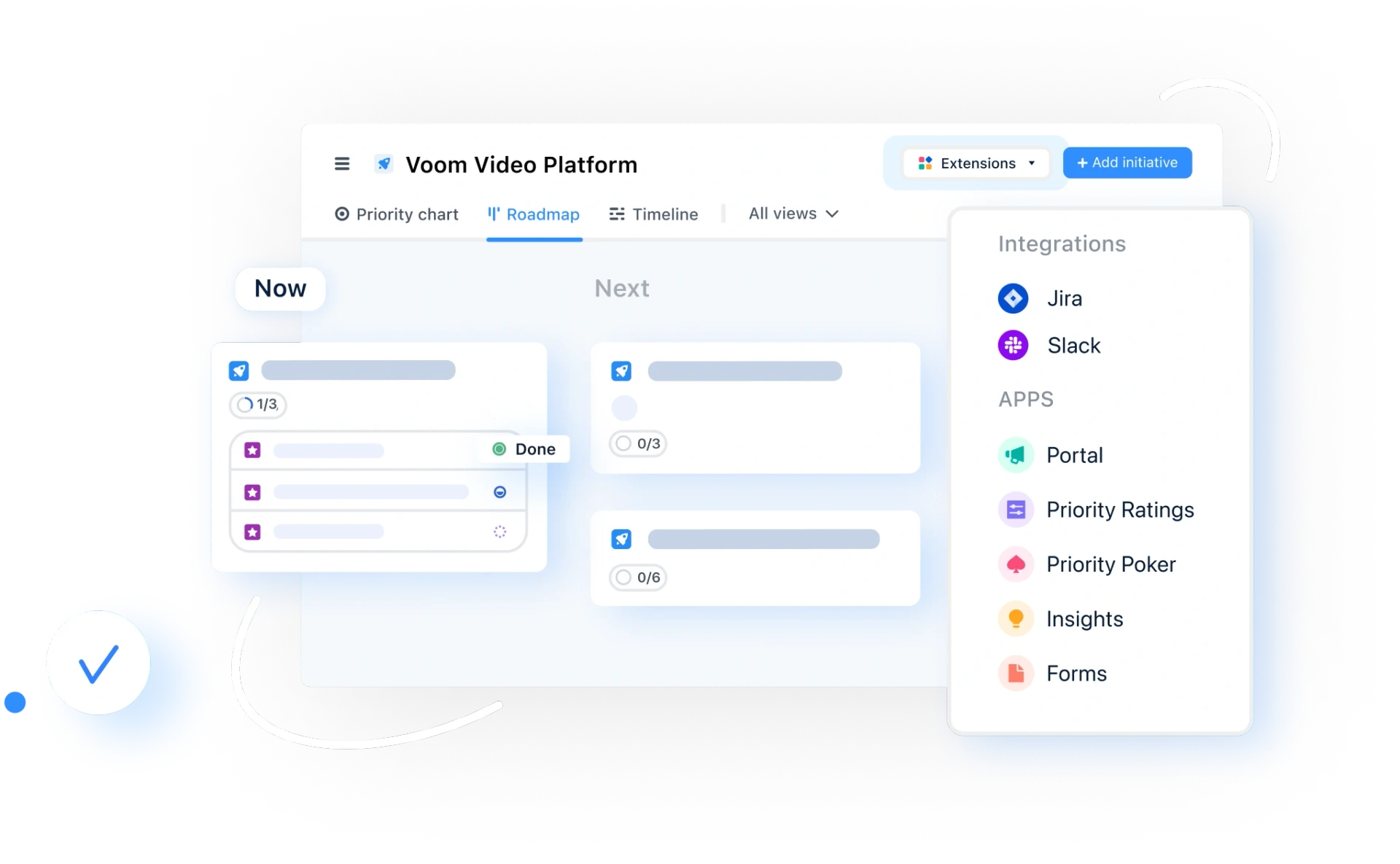

Experience the new way of doing product management

Experience the new way of doing product management