Five Whys (5 Whys)

What are the five whys?

Definition of the five whys

The five whys is a technique used to identify the root, underlying cause of a customer, business, or operational problem. As the name implies, the exercise requires teams to ask five “why?” questions to reach a solution (or “counter-measure”).

This method was created by Japanese inventor Sakichi Toyoda, who founded Toyota Industries. He established the five whys approach in the 1930s, and it’s believed that the five whys principles are still used at Toyota today.

What are the five whys used for?

The five whys technique is used for solving problems, helping to improve product quality, and troubleshooting issues without an immediately-obvious cause. Generally, the five whys are considered at their most effective when applied to problems that could be described as either simple or moderately difficult. For example our landing page CTA isn’t converting, why?

Why can’t the five whys be used for more complicated issues? Good question!

When trying to solve complex issues, you need to properly assess the many different moving parts. In the end, you may find that several root causes are to blame for the surface level issue, and a different technique (e.g. cause and effect analysis) would be more effective to iron them out.

How to perform the five whys exercise

The standard five whys technique includes a number of steps.

Typically, it will begin with the building of a team; individuals familiar with the issue at hand, and the products/processes being affected. One member of this team will be elected to serve as a facilitator, and they’re responsible for ensuring the group remains focused on the problem and working to find a counter-measure.

It’s useful to monitor the problem as it occurs, if possible. The team should observe the problem carefully and prepare notes for a comprehensive discussion. A problem statement should then be written, in a concise and direct manner. The team should agree that the problem statement is a fair definition of the issue at hand.

Next, it’s time to ask the first why: “why is the issue actually occurring?”. The aim of this question is to find a tangible, factual reason for the problem — based on research and insights. This cannot be an estimate. Ideally, a clear, obvious reason will be identified instead of several.

For example, let’s go back to the landing page CTA.

Question: Why is the CTA not converting?

Possible answer: Because site visitors don’t notice it.

Once one or more answers have been written in response to the first “why”, the next step involves asking four more “whys” for each of those answers.

Question: Why don’t site visitors notice it?

Possible answer: Because the copy isn’t compelling enough.

Why is the copy not compelling enough? Maybe we haven’t captured the benefit clearly. Why haven’t we captured the benefit clearly? Because we don’t know enough about their problem.

And there you have it: the root cause for your failing CTA.

This is of course a very basic 5 Whys in action, but here you can see how suitable counter-measures could be established to prevent the problem from occurring again in the future.

What are some common challenges in the five whys?

Sometimes, five “whys” may not be enough to get to the real, root cause of a problem. In such a case, further “why” questions may need to be asked to ensure the best results.

Conversely, though, another potential challenge could be that teams don’t know when to stop. They may keep going, even when no more valuable responses can be found!

General FAQ

Glossary categories

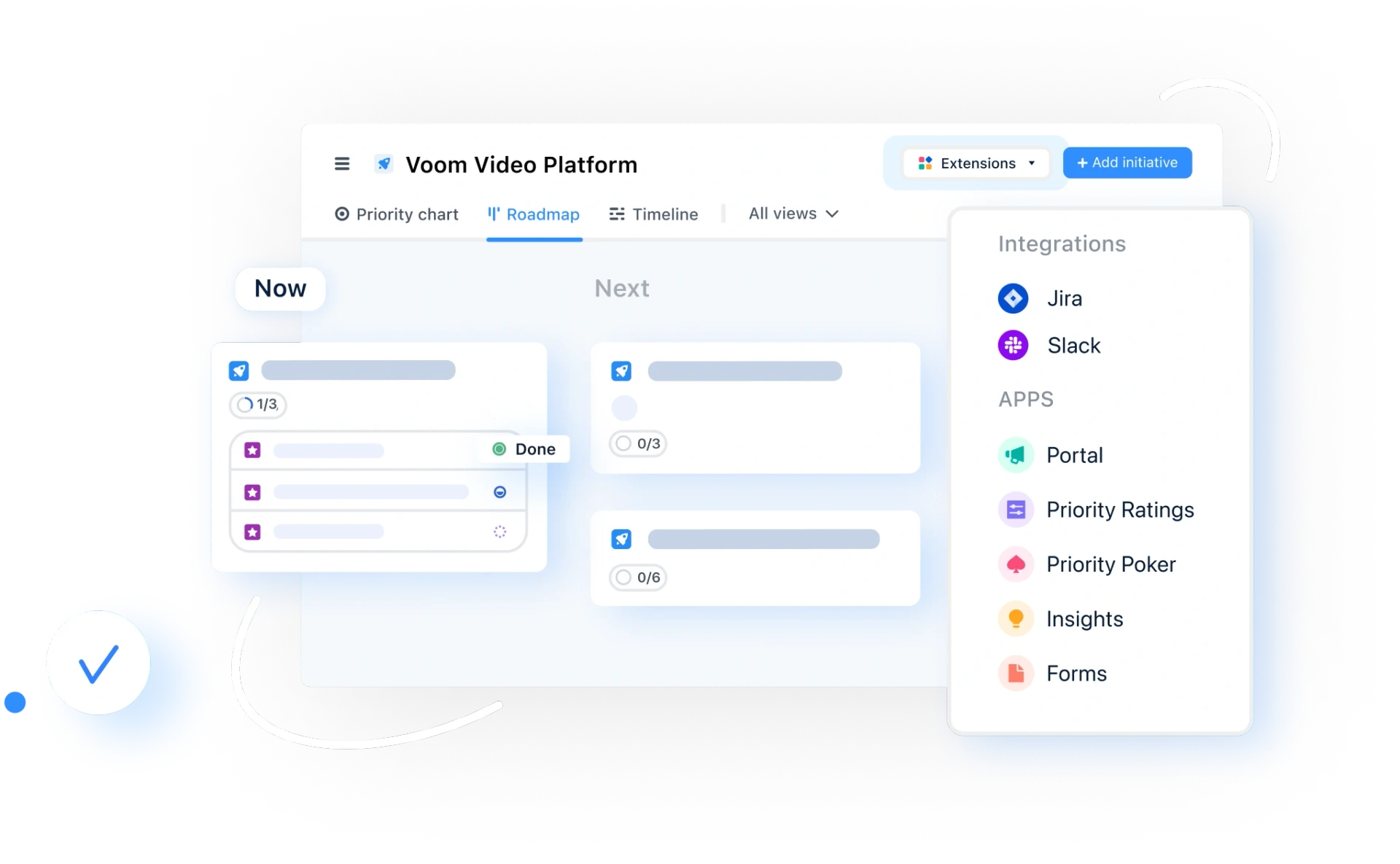

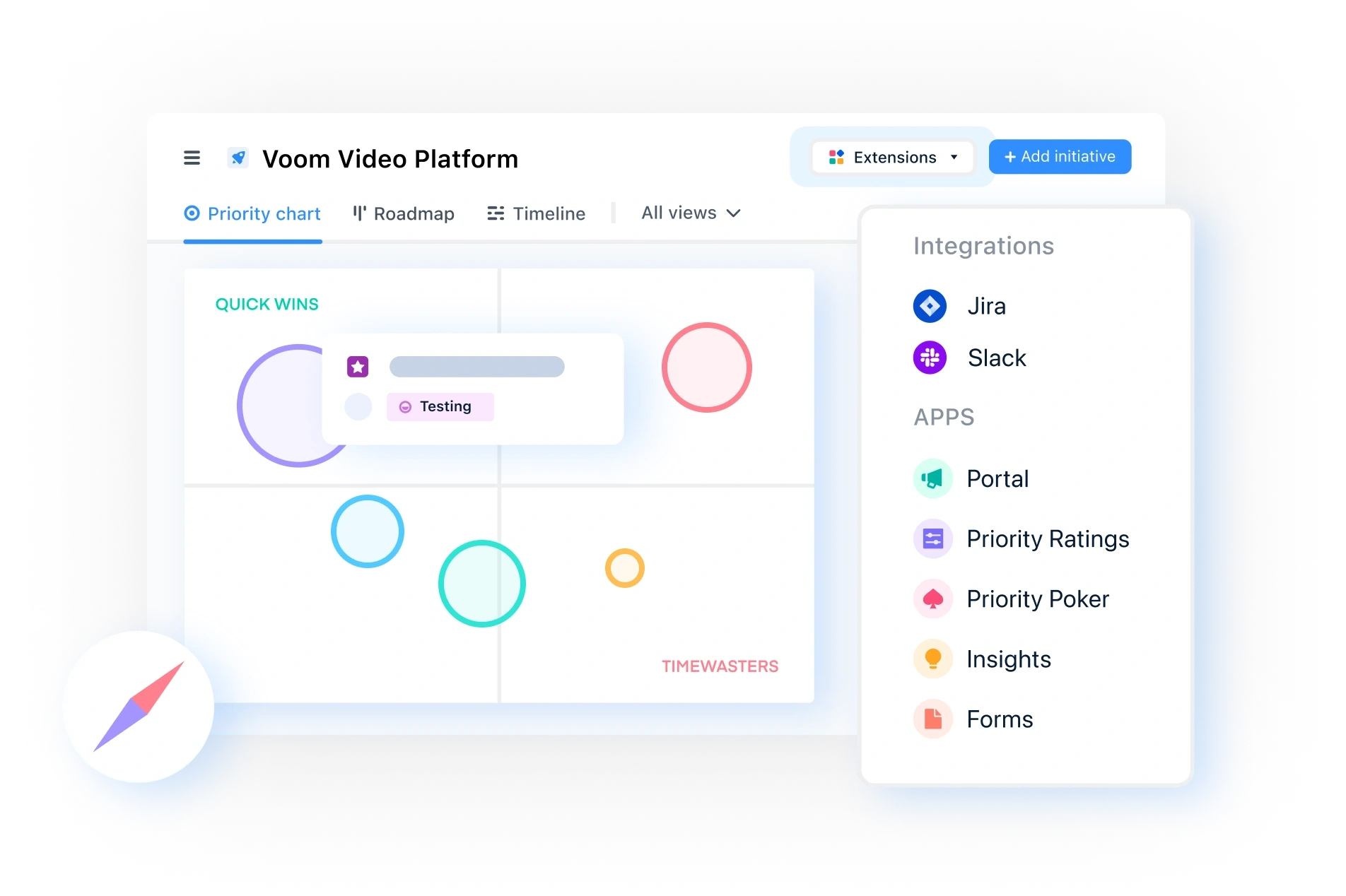

Prioritize with confidence

Experience the new way of doing product management